Checklist

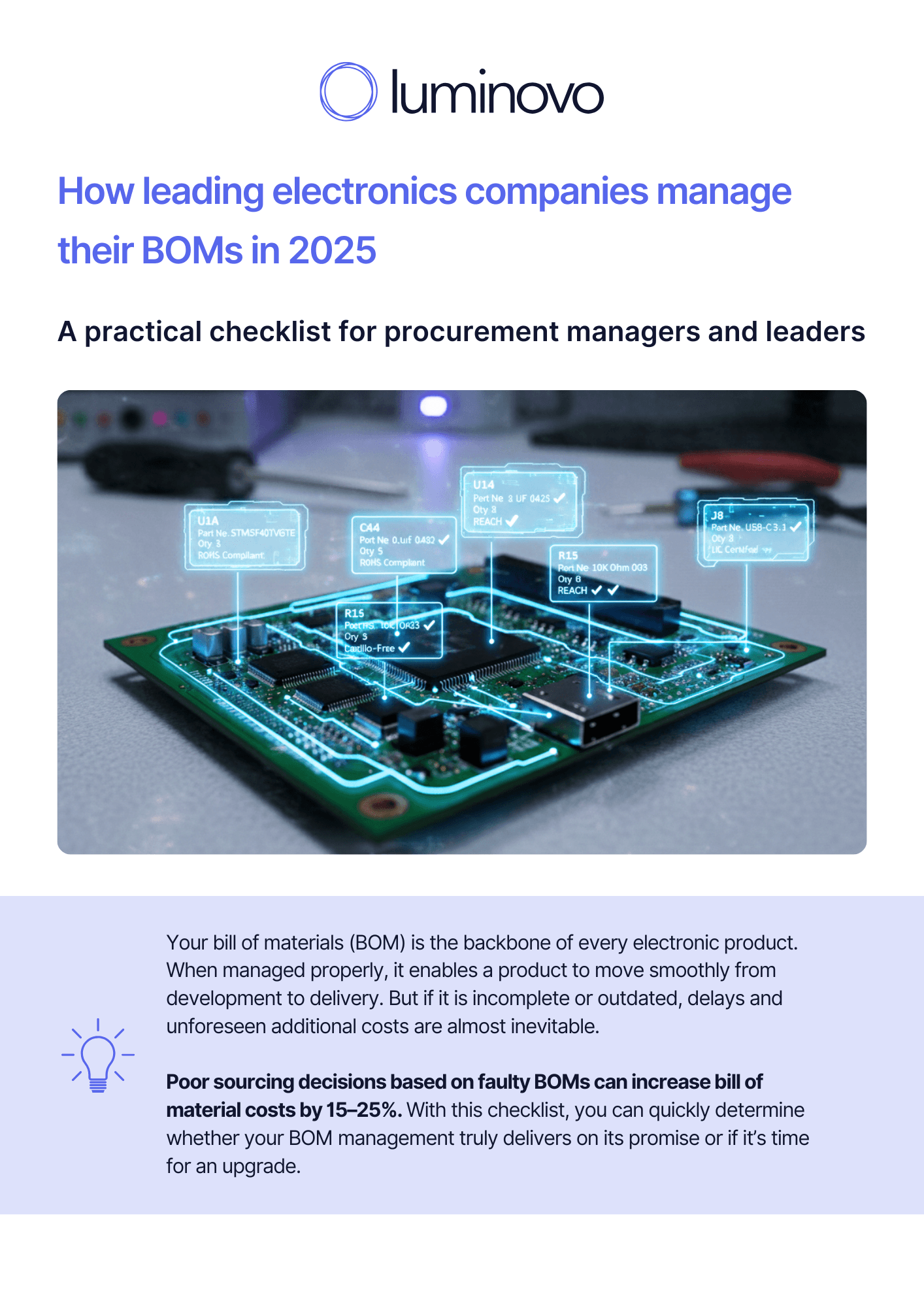

How leading electronics companies manage their BOMs in 2025

Your bill of materials (BOM) is the backbone of every electronic product. When managed properly, it enables a product to move smoothly from development to delivery. But if it is incomplete or outdated, delays and unforeseen additional costs are almost inevitable. Poor sourcing decisions based on faulty BOMs can increase bill of material costs by 15–25%. With this checklist, you can quickly determine whether your BOM management truly delivers on its promise or if it’s time for an upgrade.

Well-researched

Easy-to-understand

Practical tips